Transforming Healthcare: The Role of a Leading Manufacturer of Surgical Instruments

In the ever-evolving world of healthcare, the role of a manufacturer of surgical instruments cannot be overstated. As a vital component of the medical field, these manufacturers supply the tools that surgeons and medical professionals depend on to provide safe and effective patient care. At New-Med Instruments, we pride ourselves on being at the forefront of this essential industry. In this article, we'll explore the importance of surgical instruments, the latest innovations in surgical technology, and how our dedication to quality sets us apart in the competitive landscape of medical supplies.

The Significance of Surgical Instruments in Modern Medicine

The surgical instruments we manufacture are not simply tools; they are lifelines in the operating room. Whether it's a scalpel, forceps, or a sophisticated robotic instrument, each piece has been meticulously designed and crafted to meet exacting standards. The evolution of these instruments has paralleled advances in medical knowledge and technology, ensuring that healthcare practitioners have the best possible resources at their disposal.

- Precision and accuracy: Surgical instruments must be precise to ensure that surgeries are successful, minimizing complications and promoting faster recovery times.

- Durability: Instruments are subjected to rigorous usage, requiring materials that can withstand repeated sterilization and stress.

- Ergonomic design: Instruments must be designed for ease of use, allowing surgeons to focus on their skills rather than struggling with inadequate tools.

Innovations in Surgical Instrumentation

The landscape of surgical instruments is continuously being transformed by innovative technologies. Our role as a manufacturer of surgical instruments involves constantly adapting to these changes. Here are some of the most significant advancements:

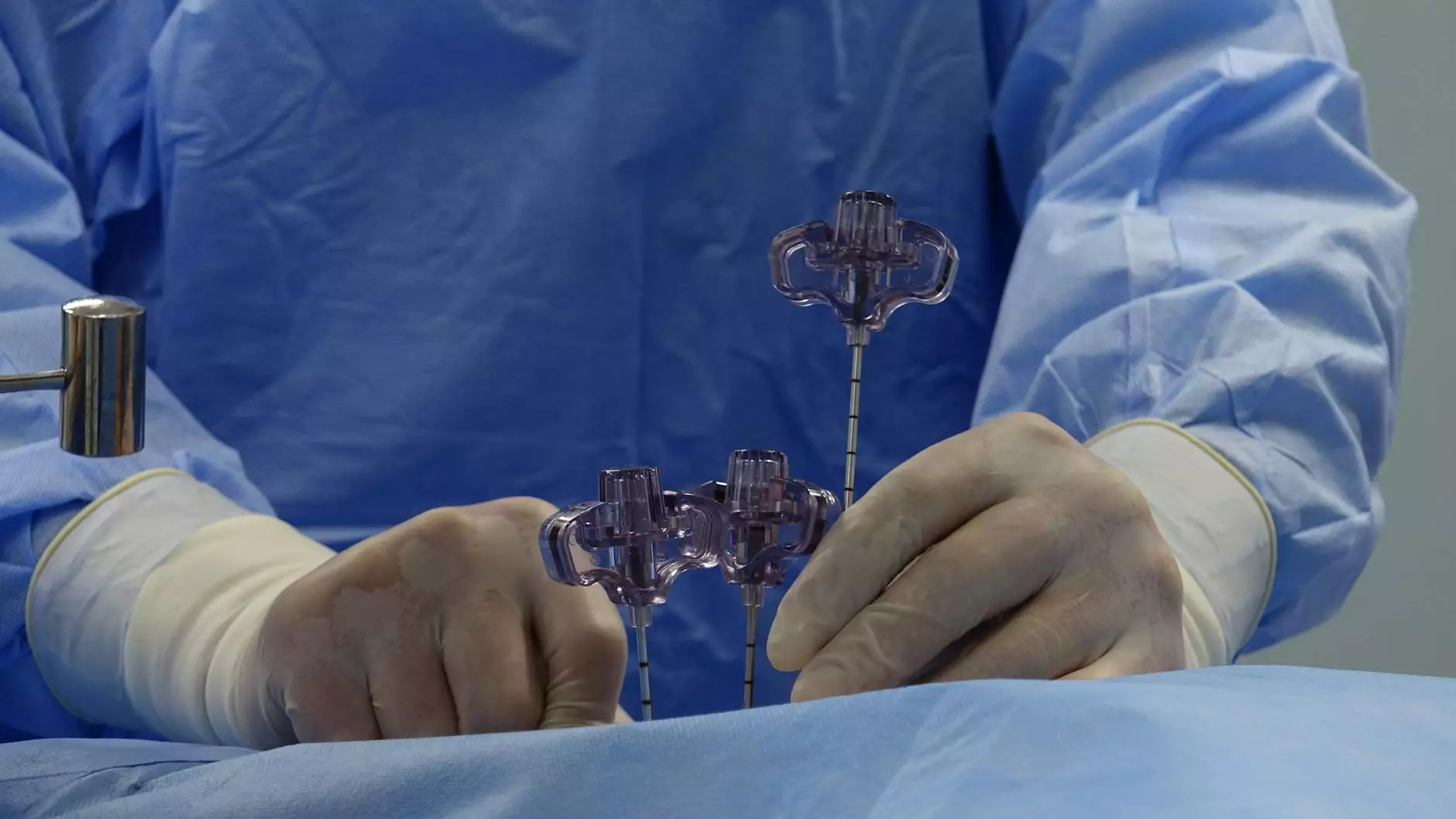

Robotic Surgery Instruments

Robotic surgery has revolutionized many procedures, offering enhanced precision, smaller incisions, and faster recovery times. Instruments designed for robotic platforms must be lightweight, flexible, and highly responsive to provide surgeons with an unparalleled degree of control.

Smart Surgical Tools

Integration of smart technology in surgical tools is on the rise. Tools embedded with sensors can provide real-time feedback to surgeons, enhancing their decision-making and ensuring optimal outcomes. These advancements not only improve patient safety but also facilitate training for new surgeons.

3D Printing Technology

3D printing has become a game changer in the manufacturing field, including the production of surgical instruments. This technology allows for the customization of tools specific to the needs of individual surgeries, reducing costs and improving procedural efficiencies.

Quality Assurance in Manufacturing Surgical Instruments

At New-Med Instruments, we understand that quality assurance is non-negotiable. Our manufacturing processes are steeped in rigorous testing and validation to ensure that every surgical instrument we produce meets or exceeds global standards. Here’s how we maintain our commitment to quality:

- Material Selection: We use only the highest-grade stainless steel, titanium, and other alloys known for their strength and resistance to corrosion.

- Precision Engineering: Our state-of-the-art machinery is operated by expert technicians who ensure that every instrument is manufactured with the utmost precision.

- Comprehensive Testing: Each instrument undergoes extensive testing to evaluate durability, functionality, and safety before it reaches the market.

Our Range of Surgical Instruments

As a comprehensive manufacturer of surgical instruments, we offer an extensive range suitable for various medical disciplines, including:

General Surgery Instruments

From scalpels to scissors, our general surgery instruments are designed to provide surgeons with reliable performance during critical operations.

Orthopedic Instruments

We specialize in instruments that cater to orthopedic surgery, providing tools necessary for joint replacements, fracture repairs, and arthroscopic procedures.

Cardiovascular Instruments

Our cardiovascular range includes instruments that are essential for heart surgeries, ensuring precision in delicate operations.

Sustainability in Manufacturing Surgical Instruments

As the global healthcare landscape faces increasing scrutiny regarding environmental impact, New-Med Instruments is committed to sustainability. Our manufacturing practices reflect our dedication to reducing our carbon footprint:

- Eco-Friendly Materials: Sourcing sustainable materials wherever possible to reduce environmental degradation.

- Energy Efficiency: Implementing energy-efficient technologies in our manufacturing processes to minimize energy consumption.

- Waste Reduction Programs: Initiating programs to recycle and reduce waste generated in the production process.

Challenges Faced by Surgical Instrument Manufacturers

While the future of surgical instruments looks promising, the industry faces several challenges that manufacturers must navigate:

Regulatory Compliance

Compliance with rigorous healthcare regulations can be daunting. Manufacturers must continually adapt to new guidelines and standards to ensure the safety and efficacy of their products.

Supply Chain Disruptions

Global events can disrupt manufacturing and supply chains. As a proactive response, we are diversifying our supplier base to maintain quality and availability.

Technological Adaptation

Keeping up with rapid technological advancements requires continual investment in research and development. At New-Med Instruments, we prioritize R&D to stay ahead of industry trends.

The Future of Surgical Instrumentation

Looking ahead, the future of surgical instrumentation is bright. Innovations in materials science, technology integrations, and advanced manufacturing techniques are set to enhance the performance of surgical instruments significantly. Here are a few trends to watch:

- Biodegradable Surgical Instruments: Researchers are working on creating instruments that reduce plastic waste and can be safely broken down after use.

- Personalized Instrumentation: The use of patient-specific surgical instruments is expected to grow, improving outcomes and efficiencies in the operating room.

- Telemedicine and Remote Surgery: Advances in remote diagnostic tools will play a crucial role as we integrate surgical instruments with telemedicine, allowing surgeons to operate from anywhere.

Conclusion

As a leading manufacturer of surgical instruments, New-Med Instruments is committed to driving advancements in the field of medical supplies. Our focus on quality, innovation, and sustainability ensures that healthcare professionals around the world have access to the best instruments available. By investing in research and aligning with modern technological advancements, we are not just meeting the needs of today, but are also shaping the future of surgical instrumentation.

For more information about our products and how we can serve your medical supply needs, visit New-Med Instruments today.